RNW PACIFIC ERW GI PIPES

TECHNICAL DATA

ASTM A53

Specification for Hot-dipped Galvanized Electric Resistance Welded Iron Steel Pipe for High Pressured Services.

Specification for Hot-dipped Galvanized Electric Resistance Welded Iron Steel Pipe for High Pressured Services.

ERW GI GRADE B – Sch.40

Zinc Coating ≥ 1.8 oz/ft2 (0.55 kg/m2)

Composition and Properties

As prescribed by ASTM Standards, the chemical and mechanical requirements for Electric Resistance Welded Galvanized Iron Pipe are as follows.

As prescribed by ASTM Standards, the chemical and mechanical requirements for Electric Resistance Welded Galvanized Iron Pipe are as follows.

Mechanical Properties Gr. B

Yield Point : ≥240MPa (35 000 psi)

Tensile Point : ≥415 MPa (60 000 psi)

Elongation : 17%-30%

Yield Point : ≥240MPa (35 000 psi)

Tensile Point : ≥415 MPa (60 000 psi)

Elongation : 17%-30%

Dimension Tolerance

Weight: +10%, -3.5%

Outside Diameter

40mm and Below : ∓0.40mm

50mm and Above : ∓1%

Wall Thickness : ∓12.50%

Weight: +10%, -3.5%

Outside Diameter

40mm and Below : ∓0.40mm

50mm and Above : ∓1%

Wall Thickness : ∓12.50%

BENEFITS OF RNW PACIFIC ERW BI PIPES

Long Life

The life expectancy of galvanized coatings on typical structural members is far in excess of 50 years in most rural environments, and 20 to 25 years plus, even in severe urban and coastal exposure.

The life expectancy of galvanized coatings on typical structural members is far in excess of 50 years in most rural environments, and 20 to 25 years plus, even in severe urban and coastal exposure.

Less Maintenance

Galvanizing is almost invariably the cheapest in the long term (because it lasts longer and needs less maintenance). Maintenance causes problems and adds to costs when structures are located in remote areas, and when plant shutdown is involved.

Galvanizing is almost invariably the cheapest in the long term (because it lasts longer and needs less maintenance). Maintenance causes problems and adds to costs when structures are located in remote areas, and when plant shutdown is involved.

Reliability

Coating life and performance are reliable and predictable.

Coating life and performance are reliable and predictable.

Complete protection

Every part of a galvanized article is protected, even recesses, sharp corners and inaccessible areas. No coating applied to structure or fabrication after completion can provide the same protection.

Every part of a galvanized article is protected, even recesses, sharp corners and inaccessible areas. No coating applied to structure or fabrication after completion can provide the same protection.

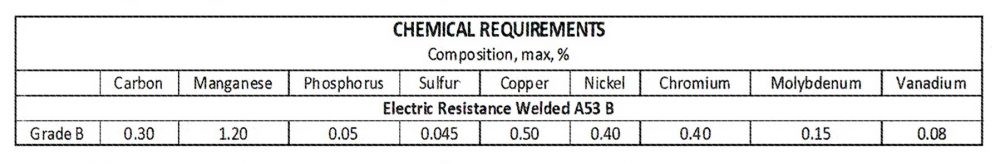

CHEMICAL COMPOSITION

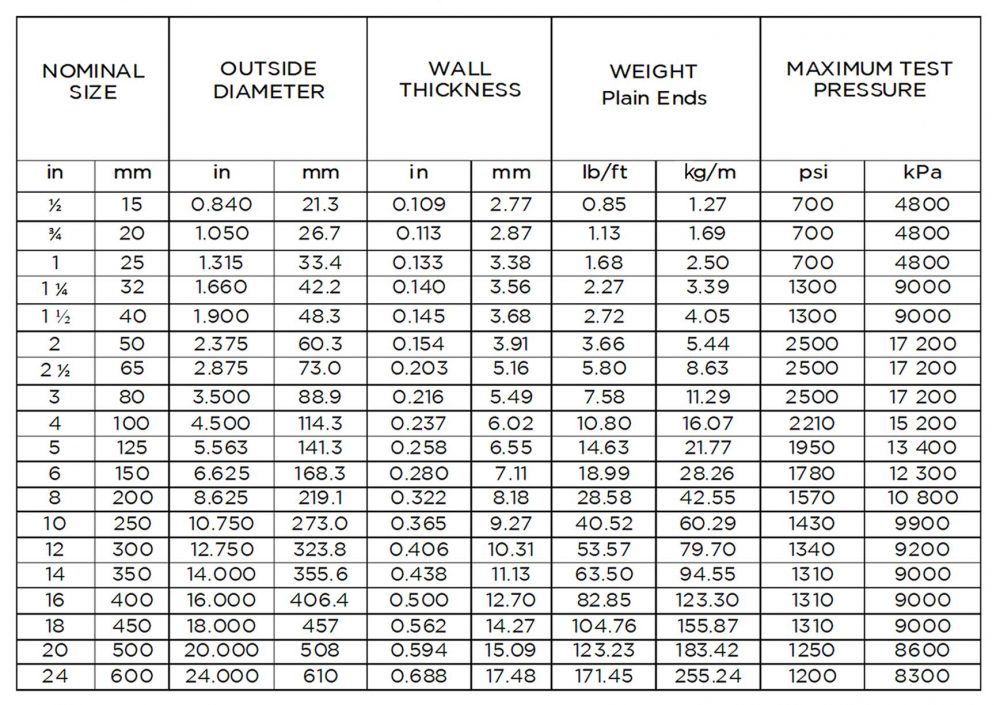

ERW BI AND GI PIPES SPECIFICATION Sch. 40